Clique nas imagens para ampliar.

All types of hydraulic motors have common design features: a driving surface area subject to pressure differential; a way of timing the porting of pressure fluid to the pressure surface to achieve continuous rotation; and a mechanical connection between the surface area and an output shaft. The ability of the pressure surfaces to withstand force, the leakage characteristics of each type of Hydraulic motor, and the efficiency of the method used to link the pressure surface and the output shaft determine the maximum performance of a Hydraulic motor in terms of pressure, flow, torque output, speed, volumetric and mechanical efficiencies, service life, and physical configuration. Medals Hydraulic motors are available in external gear type, each consist of a pair of matched gears enclosed in one housing. Both gears have the same tooth form and are driven by pressure fluid. One gear is connected to an output shaft. The other is an idler. Pressure fluid enters the housing at a point where the gears mesh. It forces the gears to rotate and follows the path of least resistance around the periphery of the housing. The fluid exits at low pressure at the opposite side of the hydraulic motor. Close tolerances between gears and housing help control fluid leakage and increase volumetric efficiency. Wear plates on the sides of the gears keep the gears from moving axially and help control leakage. All Medal hydraulic motors are designed to maximize life, efficiency, and minimize noise. Medal hydraulic motors are tested with oil at 100% load to guarantee their high performance, and subject to a thorough cleaning process to ensure very low contamination levels.

Medal also has available

- Followings are our main products:

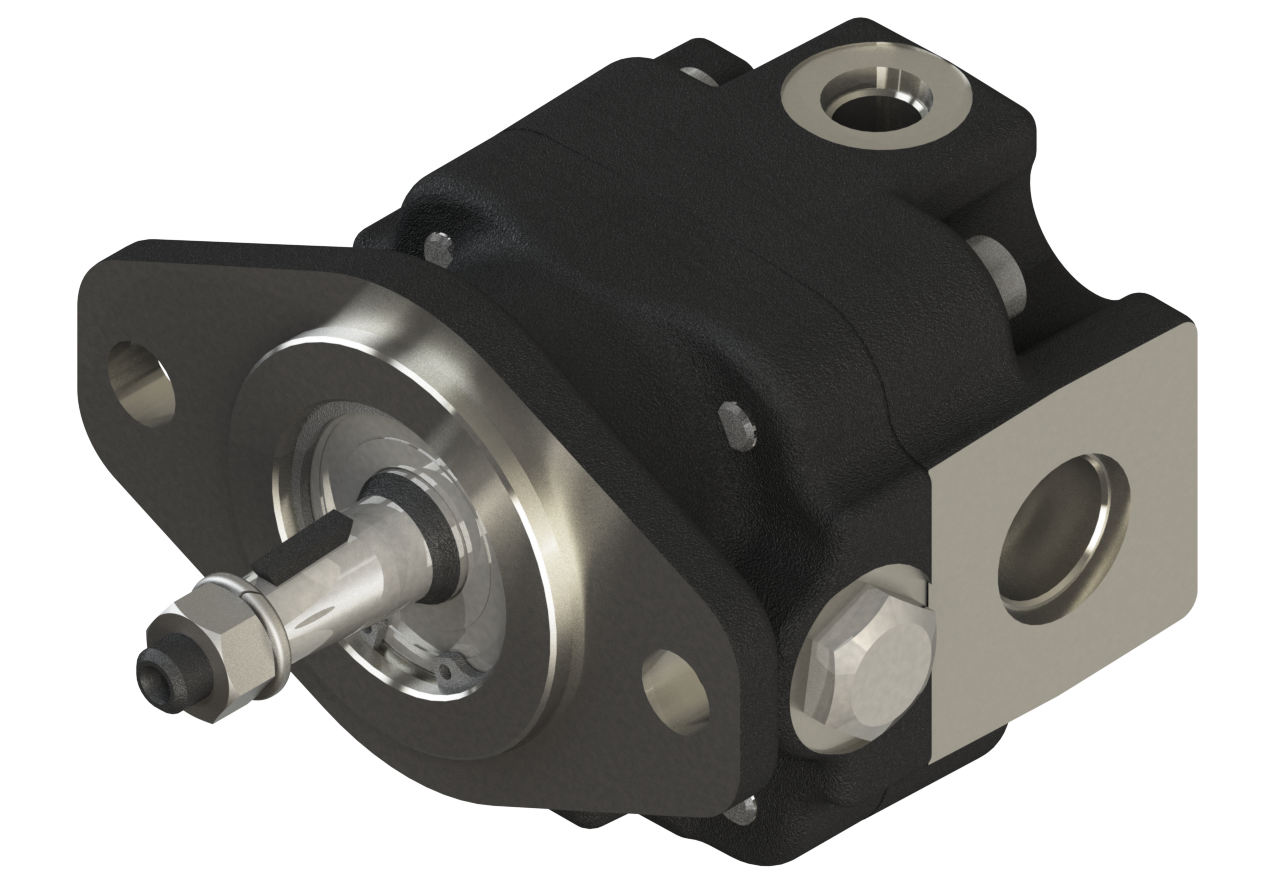

- Aluminun Hydraulic Motors MD11

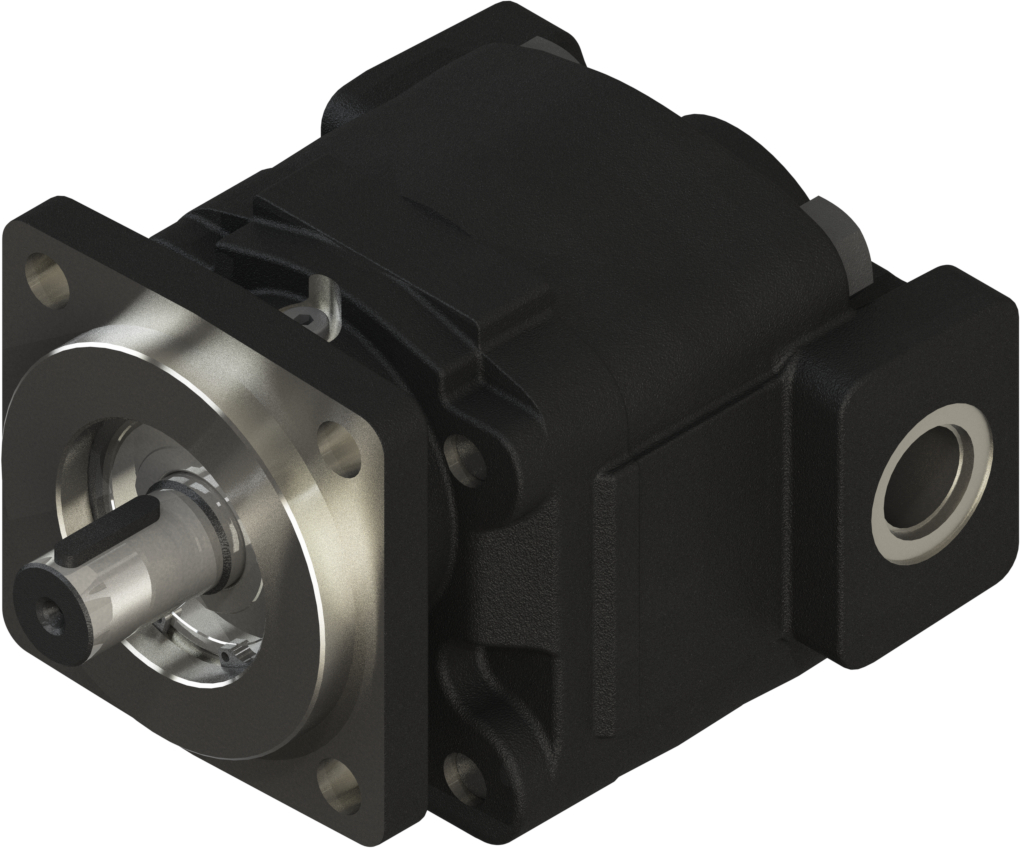

- Cast Iron Roller bearing Motorsseries MD31,MD51,MD76

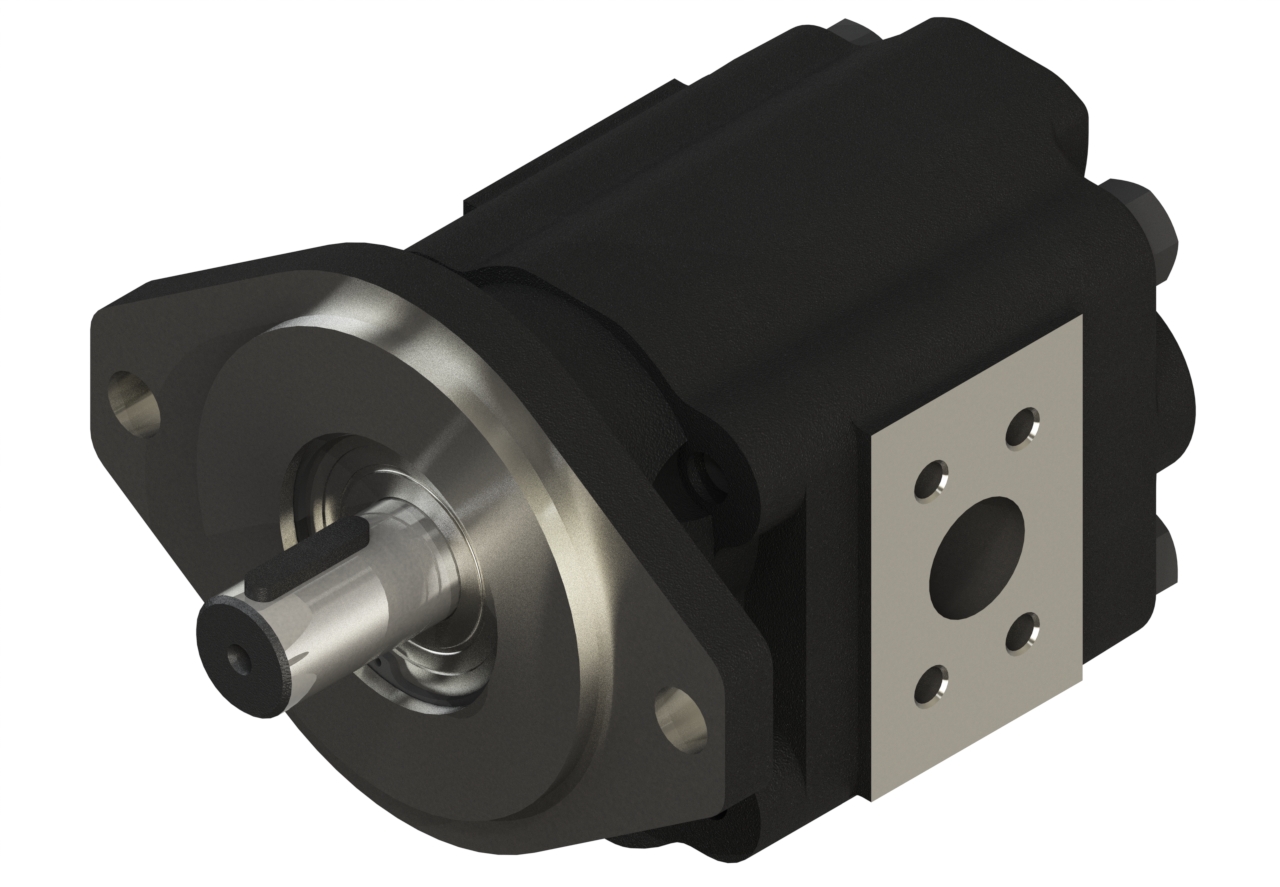

- Cast Iron Bushing bearing series Motors MD315, MD330, MD350, MD365.

- LSHT Low Speed High Torque Motor

Fechar

Fechar